UVA-S25 UV Light Source For 3D Printer

The UVA-S25V01 from Aptus International Co., Ltd. is a 5.96/6.6-inch UV LED light source designed for precision curing in 3D printing applications. This powerful light source features parallel light technology for high contrast and reduced diffuse reflection, ensuring detailed and accurate photo-curing. With an input voltage of 17-17.5V and a recommended input current of 5A, it delivers a light intensity of >100mW/cm² for efficient curing. The UVA-S25V01 is built for performance, with a 5×5 LED array and a structured design that simplifies installation in your 3D printer setup. Experience the quality and reliability of Aptus International Co., Ltd. in your 3D printing projects.

S Series UV Light Source: Precision Curing for 3D Printers

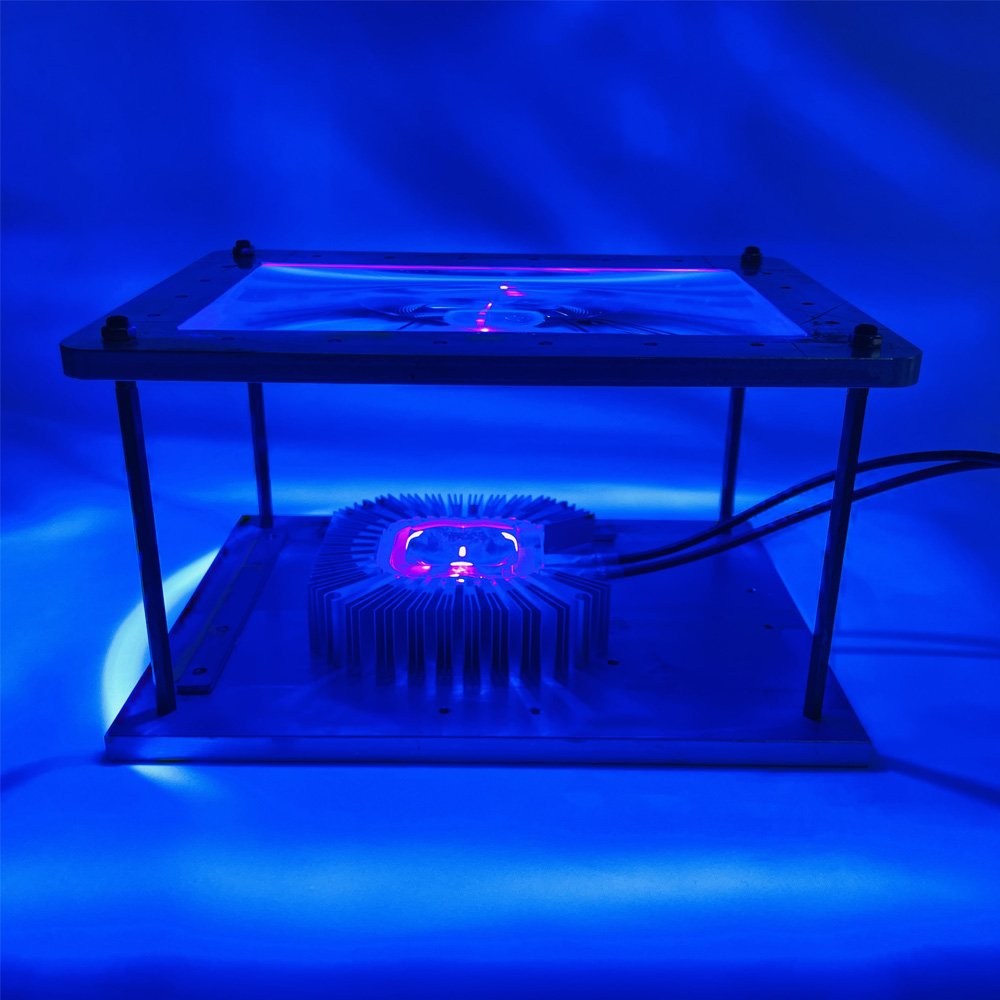

The S Series UV Light Source is a cutting-edge lighting solution designed to enhance the precision of photo-curing 3D printers. This advanced light source combines parallel light technology with a robust structural design to deliver optimal performance for 3D printing applications.

Core Parameters

Input Voltage: 17-17.5V

Input Current: 4.5-5A (5A recommended)

Light Intensity: >100mW/cm² (measured with Linshang LS125 UV radiometer probe UVALED-X3)

AA Area Evenness: ≥85%

Key Features

High Evenness: With an AA area evenness of ≥85%, the light source provides uniform curing across the surface. This uniformity is essential for achieving consistent print results and avoiding variations in curing that could lead to defects or inaccuracies in the final printed parts.

Parallel Light Technology: This light source employs parallel light technology to minimize diffuse reflection and enhance image boundary recognition. This is crucial for achieving the fine details required in 3D printing, ensuring high contrast at the edges for precise measurements and accurate prints.

High-Intensity Output: Delivering a light intensity of over 100mW/cm², this light source ensures efficient and effective curing of photo-curing components. This high-intensity output guarantees consistent and reliable curing across the entire surface, reducing the risk of incomplete curing and improving print quality.

5 × 5 LED Matrix: Consisting of a 5 × 5 matrix of LEDs arranged in a 5 series and 5 parallel configuration, this light source delivers a powerful and consistent light output. The arrangement of the LEDs ensures that the light is evenly distributed, minimizing dark spots and maximizing the effectiveness of the curing process.

Installation Recommendations

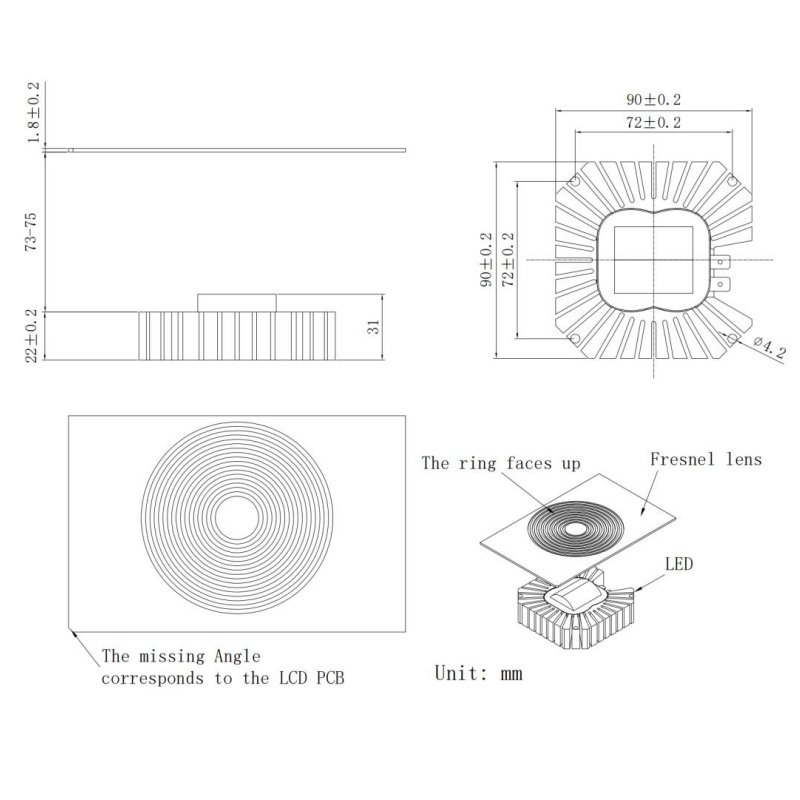

Fresnel Lens Distance: The optimal distance between the Fresnel lens and the heat sink base is 82-85mm. This distance is crucial for achieving the best performance from the light source and should be adjusted according to the actual effect to ensure optimal results.

Horizontal Positioning: When installing the Fresnel lens horizontally, align the center of the ring pattern on the lens with the center of the LED lamp of the light source. The deviation between these centers should be controlled within ±1mm. This precise alignment ensures that the light is focused correctly, maximizing the effectiveness of the curing process.

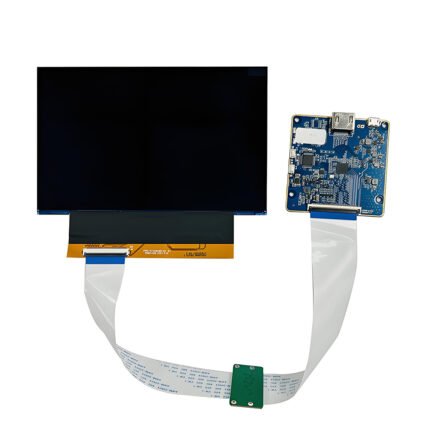

Distance to LCD: The distance between the Fresnel lens and the LCD should be within 0-6mm. Maintaining this distance is essential for achieving the best light distribution and curing results, as increasing the distance beyond this range may affect the performance of the light source.

Suggested Installation Method: Place the Fresnel lens, glass cover, and LCD sequentially on the metal platform. Using the glass cover provided by our company can offer support and protection for the LCD, preventing it from shifting during operation. Depending on the structural design, you can choose a glass cover that is either the same size as the LCD Fresnel lens or larger. The distance between the Fresnel lens and the LCD is generally determined by the glass cover and the Fresnel lens, with a recommended thickness of 3-4mm.

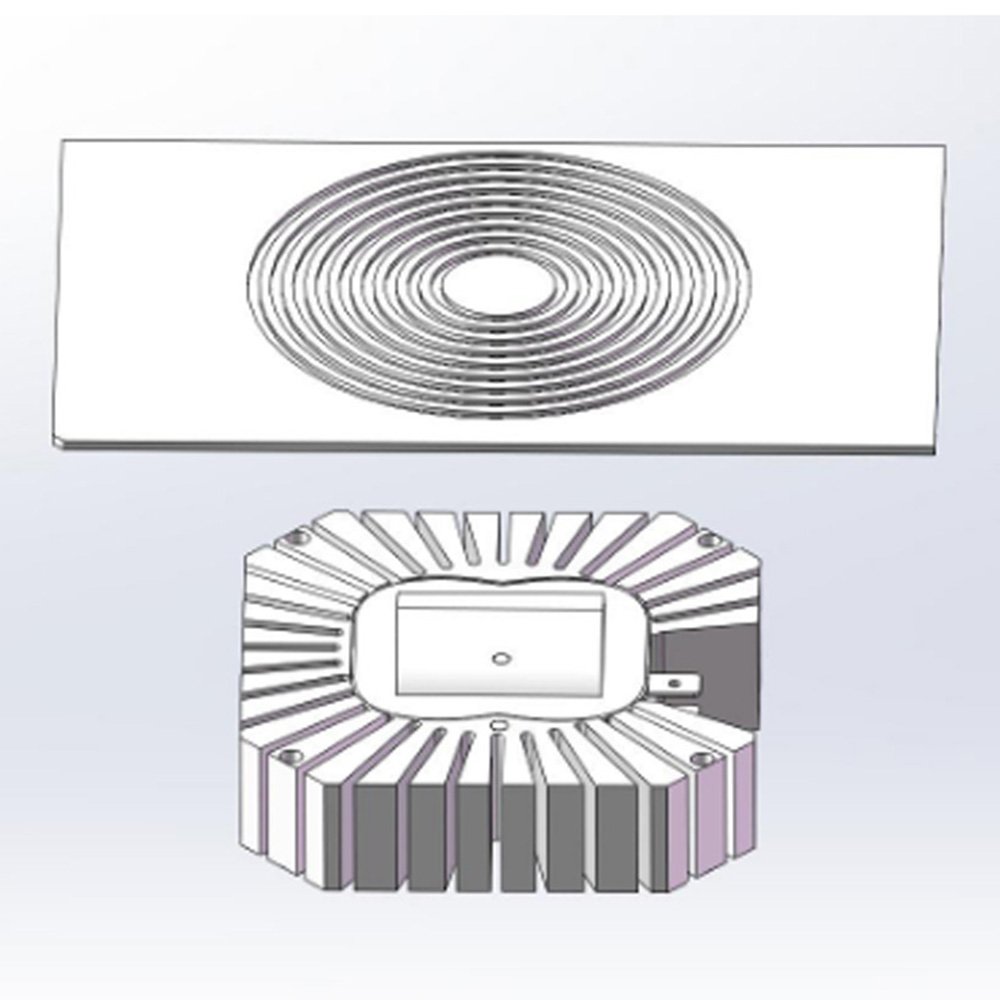

Product Structure and Design

The UVA-S25V01 features a robust structure, with a 3D dimensional drawing provided for precise installation. The product engineering drawing is available for detailed reference, ensuring a perfect fit for your 3D printer setup. This ensures that the light source can be easily integrated into your existing 3D printing workflow, providing a reliable and consistent lighting solution for your photo-curing applications.