What is Mono LCD and How Does It Work in 3D Printing?

What is Mono LCD and How Does It Work in 3D Printing?

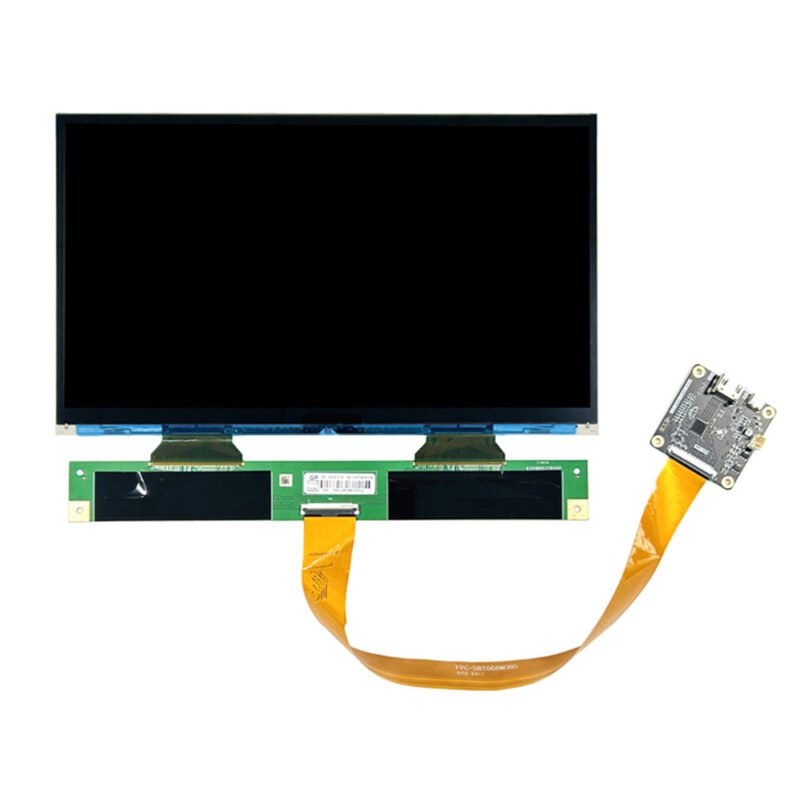

Mono LCD, short for monochrome liquid crystal display, is a specialized type of LCD panel that transmits light in grayscale rather than full color. While traditional LCDs are optimized for visual display purposes like TVs and smartphones, mono LCDs are engineered for industrial precision—particularly in applications such as resin-based 3D printing.

How Mono LCD Works: A Simplified Overview

At its core, a mono LCD consists of:

- A backlight or UV light source

- A monochrome liquid crystal matrix

- A pixelated mask layer (TFT or ITO-based)

- A polarizer and glass substrates

When the mono LCD receives electrical signals, the liquid crystals align to either block or transmit UV light at each pixel point. This binary (on/off) or grayscale exposure method is ideal for masking photopolymer resin in MSLA (Masked Stereolithography) 3D printers.

Unlike color LCDs, mono LCDs have no RGB filters. This absence leads to:

- Greater light transmittance

- Faster curing times

- Longer lifespan under UV exposure

These characteristics directly enhance 3D print speed, accuracy, and durability of the screen itself.

Mono LCD vs. Color LCD in 3D Printing

| Feature | Mono LCD | Color LCD |

|---|---|---|

| Light transmittance | 6–10% | ~2–3% |

| Exposure time | Shorter (~1.5–3s/layer) | Longer (~6–10s/layer) |

| UV resistance | High | Low |

| Lifespan | 2,000+ hours | < 500 hours |

| Resolution Capability | Higher grayscale control | Lower due to RGB filter interference |

Why Mono LCD is Ideal for 3D Printing

In modern 3D printers—especially those using UV-curable resins—the mono LCD plays a critical role as a dynamic UV mask. Here’s how it works in the printing process:

- UV light emits upward from an LED matrix.

- The mono LCD acts as a digital mask, allowing light to pass only in desired pixel areas.

- The light cures resin layer by layer, based on the cross-section of the 3D model.

Compared to DLP and laser-based SLA printers, mono LCD printers offer:

- High-resolution printing at lower cost

- Simplified mechanical structure

- Scalability for consumer and industrial-grade printers

DUOBOND Approach to Mono LCD for 3D Printing

At Duobond, we design and supply custom mono LCD panels tailored specifically for resin 3D printer manufacturers. Unlike off-the-shelf displays, our panels are:

- Optimized for uniform UV transmittance

- Available in 4K, 6K, 7K,8K,9K,12K,14K and 16Kresolutions

- Designed with thermal stability and high contrast ratios

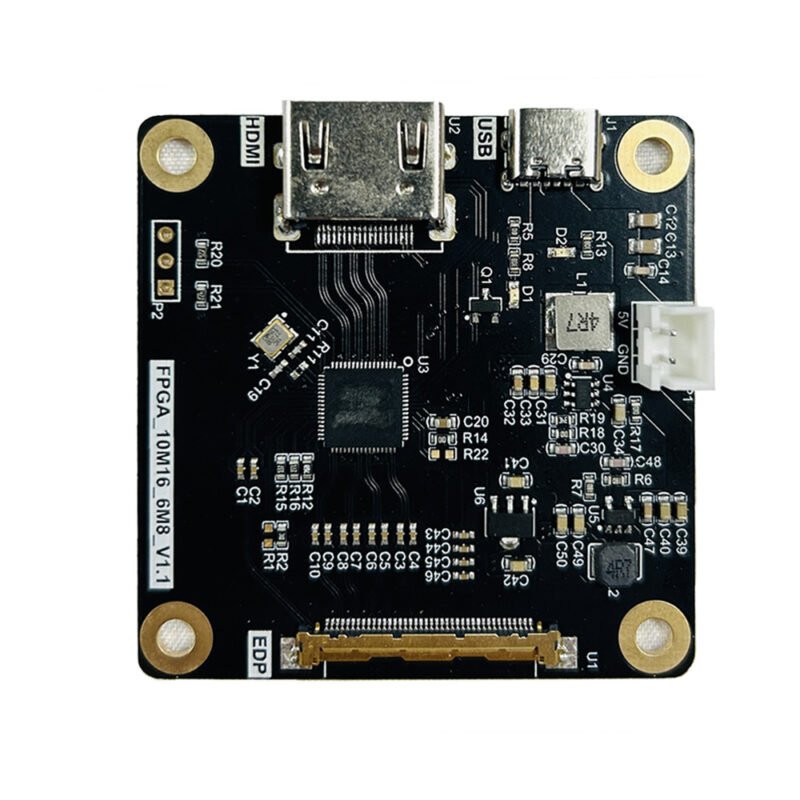

- Integrated with HMI boards and UV light systems for plug-and-play deployment

This vertical integration ensures faster development cycles for printer brands and superior printing performance for end users.

HD-MI board

UV Light System

Final Thoughts

Mono LCD technology is not just a component—it’s the visual engine that drives the precision and speed of modern resin 3D printers. As the additive manufacturing industry continues to scale, custom-engineered mono LCDs will be central to innovations in dental, jewelry, prototyping, and industrial parts printing.

If you’re building your next-generation 3D printer, mono LCD is no longer optional—it’s foundational.